We believe that design is what differentiates us, so we have focused on recruiting and developing design talent.

The design team is highly motivated, wanting to offer cutting-edge packaging to our Indonesian customers, and we will continue to invest in our talent.

Our motto is “Better things, Faster.” We work quickly from proposal to design and delivery.

We also invest in equipment such as sample machines and testing machines to enable speedy, high-quality design.

The client had an issue with many defective products being found when unpacking at the export destination. The damaged products had to be discarded, and each time this happened, problems arose with transportation costs and inventory shortages. We consulted with the client and proposed changing to a new cushioning material without changing the material cost, which resulted in a significant reduction in product damage.

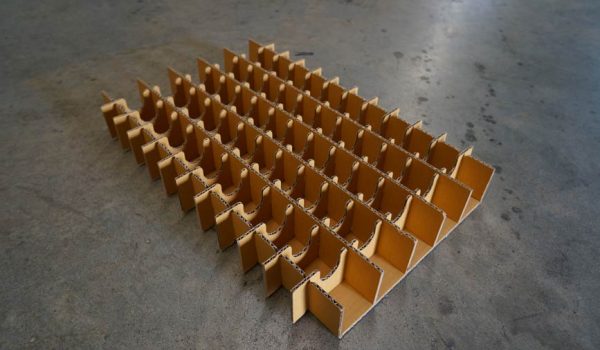

Even with products with such complex shapes, our designs make it possible to export them overseas without any problems. To reduce costs, we changed from CB flutes to C flutes, but still ensured the strength to withstand transportation when stacked five high. We were able to achieve a design that maintains sufficient strength while keeping material costs to a minimum.

The previous product was made by stacking CB-flute material and gluing it, but by changing to C-flute and folding one sheet without using glue, we were able to reduce material costs and labor costs. We have succeeded in reducing costs through efficiency.

Please inquiry freely.

Please feel free to contact us for consultation, quotation.

A person in charge with specialized knowledge will visit you.

If you have any questions, please let us know.

Propose optimal packaging

We will propose the most suitable packaging for you, reflecting your requests.

We improve until you are satisfied

We will decide the specification after improvements. And then formally sign on a contract.

Delivery

We will adjust the schedule according to the delivery date. It will be mass-produced after the final confirmation. Delivery can be split according to your request.